Introduction to the Use of Oil Casing in Industry

With the development of industrial modernization faster and faster, there are more and more different types of steel pipes, oil casing is one of them, the following and Cangzhou Xiaobian together to understand the role of oil casing in the industry is what.

Jan 16,2023

With the development of industrial modernization faster and faster, there are more and more different types of steel pipes, oil casing is one of them, the following and Cangzhou Xiaobian together to understand the role of oil casing in the industry is what.

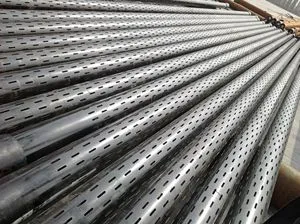

Casing is a special steel pipe for oil and gas well cementing, which is used to seal oil, gas and water layers; protect the well wall; and prevent blowout or well wall collapse. According to the use, the casing is divided into surface casing, technical casing and oil layer casing. When drilling is started, after drilling the upper surface soil layer, because these layers are soft after all and easy to collapse, in order to prevent blowout and ensure smooth drilling, it is necessary to run a layer of surface casing. The running depth of surface casing varies from instant noodles to several hundred, with some reaching more than 1,000 meters, but most wells do not exceed 200 meters. When the bottom layer is relatively solid, the pressure of oil, gas and water layer is sure, and the drilling cycle is short, the surface casing can be removed.

After the surface casing is run, various complicated situations will be encountered during continuous drilling, such as lost circulation, well collapse, high-pressure oil, gas, water layer, etc. When conditioned mud and other measures are adopted, if the area is still ineffective, technical casing needs to be run before drilling the complex formation to isolate the difficult-to-control complex formation and ensure the smooth progress of drilling, under the condition that the formation is not complex and the depth of live drilling is not large, the technical casing can generally be removed; but for exploratory wells, there should be spare technical casing.

Related Posts

Development trend of geothermal well casing

With the increasing energy consumption and environmental problems, the development of new renewable energy is becoming more and more important. Geothermal energy as a clean, renewable energy, its application prospects.

How to install and maintain geothermal well casing correctly?

Geothermal well casing is an important part of geothermal power generation system. It is a channel connecting geothermal water wells and geothermal power generation systems, providing important support for hot water transportation.