Dry goods sharing, a minute to take you to understand the mine casing manufacturers

Mine casing is a component used to fix and protect the shaft and shaft wall of the mine.

May 06,2023

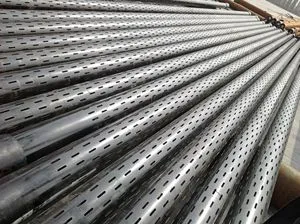

Mine casing is a component used to fix and protect the shaft and shaft wall of the mine. Its main function is to prevent the collapse of the shaft caused by soil collapse during the work process, and to protect the shaft from groundwater and other external factors. The following will introduce the structure, principle and maintenance method of the mine casing manufacturer.

What is the structure of the mine casing manufacturer? Let's take a brief look at it.

The main structure of the mine casing includes the casing pipe body and the casing pipe. The casing body is usually made of steel or other alloy materials, and its length and diameter are determined according to actual needs. The casing nozzle is located at the top of the pipe body and mainly serves to connect the pipe body and other downhole equipment.

What is the principle of mine casing manufacturers? Let's take a brief look at it.

The principle of the mine casing manufacturer is to arrange the casing pipe body around the well body as a tool to protect and support the well body. Casing is generally designed in two forms, single-layer casing and double-layer casing. Single-layer casing is mainly a pipe body arranged around the wellbore, and is maintained in the entire length of the same diameter and thickness. Double-layer casing is to arrange two pipe bodies in different positions, usually one in the outer layer and one in the inner layer. The gap will be filled with filler, play a supporting role. The gap between the two pipe bodies is usually filled with epoxy resin, cement and other fillers to strengthen the protection.

The maintenance method of mine casing is usually divided into two aspects, one is the maintenance in the production process, and the other is the maintenance in daily use. Maintenance in the production process:

1. According to the requirements of the production process and operating procedures for operation and management.

2. Establish and improve the quality management system, and test the quality of incoming materials, process and export to ensure good product quality.

3. The equipment and mechanical equipment shall be regularly inspected, cleaned and maintained, and put into use after being qualified.

4. The testing equipment shall be tested in accordance with the standard specifications to make the test results correct and reliable.

Maintenance in daily use:

1. Regularly clean and maintain the casing, keep it clean, and deal with the problems found in time.

2. Check whether the casing has obvious damage and cracks, and repair the borehole in time if any, so as not to affect the product quality.

3. Maintain the casing interface intact and keep the connection tight to prevent product quality problems caused by interface damage.

4. Regular inspection and maintenance, timely handling of problems found.

In short, the structure of the mine casing manufacturer is simple and clear, the principle is clear, and there are specific requirements for the maintenance and maintenance in the production and use process. Only by understanding the structure, principle and maintenance method of the mine casing can we better maintain the quality of the mine casing, so as to ensure the safety and stability of the mine and reduce the occurrence of various accidents.

Related Posts

Development trend of geothermal well casing

With the increasing energy consumption and environmental problems, the development of new renewable energy is becoming more and more important. Geothermal energy as a clean, renewable energy, its application prospects.

How to install and maintain geothermal well casing correctly?

Geothermal well casing is an important part of geothermal power generation system. It is a channel connecting geothermal water wells and geothermal power generation systems, providing important support for hot water transportation.