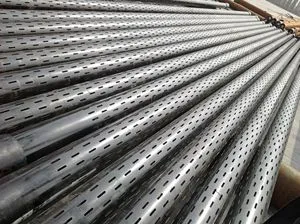

The geothermal well pipe manufacturer takes you to understand the geothermal well pipe.

Through-wall geothermal well pipe refers to the pipeline through the concrete floor and ordinary brick wall, generally reserved holes in the concrete floor, ordinary brick wall can be drilled through the wall hole.

Feb 24,2023

Through-wall geothermal well pipe refers to the pipeline through the concrete floor and ordinary brick wall, generally reserved holes in the concrete floor, ordinary brick wall can be drilled through the wall hole. On the floor, before installing the pipeline, lower the pipeline and install the sleeve. Draw line on brick wall, support, find slope and install casing.

Before the installation and use of the through-wall geothermal well pipe, the appearance, irrigation and flushing of the outer wall should be observed first, and the cracks and sand holes should be checked one by one. Check all pipe fittings for cracks, sand holes and uniform wall thickness.

Confirm that all sockets are in place, secure and compact. During the installation of through-wall geothermal well pipe, the pipeline slope shall be uniform without reverse slope, and the pipeline slope at the roof outlet shall be increased appropriately. The installation of through-wall geothermal well pipe shall be provided with supports and hangers according to the construction acceptance specifications.

Generally speaking, a corrugated compensator is installed on the ground to compensate for the displacement of the medium in the pipeline due to temperature changes. The sealing connection with the pipeline can be flange connection and connecting pipe connection. The geothermal well pipe manufacturers mainly use axial internal and external pressure ripple compensator and large and small pull rod horizontal compensation axial compensator, such as axial compensator and axial composite compensator, which are mainly used to compensate the axial displacement of pipeline displacement, as well as the combination of lateral displacement or axial and lateral displacement. It has the ability to compensate for angular displacement. It is the product of aviation, power generation, fire protection, chemical industry and other industries.

The way for geothermal well pipe manufacturers to install compensators underground is to use underground pipelines to lay compensators. The main connection method is to connect the compensator to the underground pipeline. Under special circumstances, flange connection shall be adopted for connection with pipeline, but observation well shall be set. Otherwise, even if the compensator is installed, it cannot be stretched or compressed, so that the compensation tube will not expand the displacement of the medium in the channel due to temperature changes.

There are two types of compensators commonly used by geothermal well pipe manufacturers. One is a directly buried compensator, and the other is an unconstrained compensator. These two compensators are mainly suitable for axial compensators of directly buried pipelines. It has the ability to resist bending with large compensation and strong self-guiding ability. Therefore, it is not necessary to consider the influence of the sinking of the pipeline, so that the spacing of the guide bracket can be installed at will, which is a very common and excellent product for buried pipelines with long service life.

Related Posts

Development trend of geothermal well casing

With the increasing energy consumption and environmental problems, the development of new renewable energy is becoming more and more important. Geothermal energy as a clean, renewable energy, its application prospects.

How to install and maintain geothermal well casing correctly?

Geothermal well casing is an important part of geothermal power generation system. It is a channel connecting geothermal water wells and geothermal power generation systems, providing important support for hot water transportation.