What are the main points of the use of sand screen?

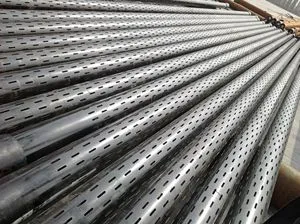

Sand control screen equipment manufacturers slit pipe using API standard oil casing body processing, high strength, not easy to deformation. There are also customers who choose stainless steel as the body for processing.

Jan 16,2023

Sand control screen equipment manufacturers slit pipe using API standard oil casing body processing, high strength, not easy to deformation. There are also customers who choose stainless steel as the body for processing. The slitting edge has good verticality, smooth cutting edge, no burr, and even slitting. The flow area is large, 27.8 "screen pipe has 300 slits and 1.5m, and the flow area is 72 per cubic centimeter, which is 2.4 times larger than the flow area of oil pipes of the same specification. Facilitating fluid flow. The advantages of using it in inclined and horizontal wells are obvious.

At present, sand control pipe sheath is used in well drilling projects. It is not only convenient to use, but also can provide more safe and effective well drilling work for the engineering team. So, do you know what kind of problems will arise in the use of the process? How to avoid the occurrence of problems?

Sand control screen pipe equipment manufacturers will take you to understand the advantages of sand control pipe sheath: the filter pipe has the characteristics of strong water permeability, because the sand control pipe sheath is stamped by uniform distribution bridge, and the water inlet point is evenly distributed. Compared with the traditional cut-hole filter pipe, it has the advantages of uniform water inflow and strong water permeability. At the same time, it has a good sand resistance effect. The aperture of the traditional cut-hole filter pipe is generally greater than one centimeter, when water enters the well, it is easy to cause water and sand to enter the well at the same time. If the external wrapping net is scratched or rotted, it is more easy to cause the inflow of the external filter material of the well pipe, thus causing the external hole collapse and the internal buried pump. The bridge-shaped gap of the sand prevention pipe sheath is 0.5mm to 1.5mm, and the sand prevention effect is extremely obvious. The important point is long service life, the anti-corrosion ability of the pipe body can be improved, thereby prolonging the service life of the water well; the operation is convenient. Compared with other filter pipes (such as cement filter pipe, cast iron pipe, steel pipe cut hole filter pipe, etc.), sand control pipe sheath is lighter in weight than pipe operation.

Related Posts

Development trend of geothermal well casing

With the increasing energy consumption and environmental problems, the development of new renewable energy is becoming more and more important. Geothermal energy as a clean, renewable energy, its application prospects.

How to install and maintain geothermal well casing correctly?

Geothermal well casing is an important part of geothermal power generation system. It is a channel connecting geothermal water wells and geothermal power generation systems, providing important support for hot water transportation.