Oil cracking pipe surge pushed up the performance of listed steel companies continue to improve

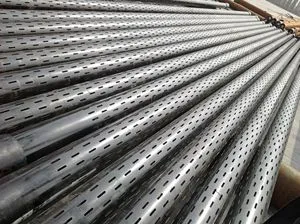

The main parameters of the slotted screen include the thickness of the pipe wall, the caliber, the material, the number of slots, the length of the screen tube and the specifications of the slot, which are required by the model.

Nov 12,2021

In petroleum screen pipe, petroleum screen pipe is a product produced by special processing industry. The main parameters of the slotted screen include the thickness of the pipe wall, the caliber, the material, the number of slots, the length of the screen tube and the specifications of the slot, which are required by the model. The general slotted screen is mainly used in the slotted machine above, usually the oil screen plant at least about 10 sets of slotted machine, so the application of oil screen is still relatively wide.

The raw material of the oil screen is the oil casing, which is basically the oil casing as the base material for the production and processing of the oil screen. There are many kinds of arrangement forms of oil screen pipe, and the common ones are parallel seam, cross seam and cross seam. The verticality of the slit edge is very good, the extension edge is very smooth, there is no burr phenomenon, and the slit is even. The slotted screen will form a very dense protective layer on the surface of the screen during the overall anti-corrosion treatment. With the protection of this protective layer, the corrosion resistance and wear resistance of the screen tube are improved to a great extent, and the service life of the oil screen tube in the underground operation of oil drilling can be effectively extended, thus reducing the cost consumption. In the exploitation of oil, the use of oil screen can filter out the 99% sand and dust, reduce the maintenance rate of tubing 80%, and improve the stability of the tubing filter sand and dust, continuity and strength, very effectively improve the efficiency of the work. Therefore, because of the great role and characteristics of the oil screen, it is necessary to pay special attention to the purchase of the oil screen, and it is also a process that the manufacturer attaches great importance.

The petroleum screen pipe produced by our company is processed by N80 petroleum casing pipe. The quality of N80 petroleum casing pipe itself is the leader in casing pipe. After being processed and formed into slotted screen pipe, the service performance has been greatly improved, so it has the advantages of high strength and not easy to deform. Whether in the inclined well or horizontal well operation can play a very powerful role, for the oil drilling industry to contribute to the strength.

NEXT:

Related Posts

Development trend of geothermal well casing

With the increasing energy consumption and environmental problems, the development of new renewable energy is becoming more and more important. Geothermal energy as a clean, renewable energy, its application prospects.

How to install and maintain geothermal well casing correctly?

Geothermal well casing is an important part of geothermal power generation system. It is a channel connecting geothermal water wells and geothermal power generation systems, providing important support for hot water transportation.