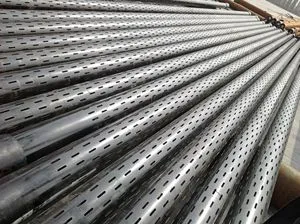

How to maintain the oxide film on the surface of stainless steel screen

Stainless steel screen surface with bleach and a variety of acid adhesion, immediately rinse with water, and then ammonia solution or neutral carbonated soda solution immersion, washing with neutral detergent or warm water.

Jan 16,2023

Stainless steel screen surface with bleach and a variety of acid adhesion, immediately rinse with water, and then ammonia solution or neutral carbonated soda solution immersion, washing with neutral detergent or warm water.

When washing with warm water neutral detergent can be washed away. Stainless steel surface dirt caused by rust, available 10% nitric acid or abrasive detergent washing, can also be used for special washing drugs. As long as we use the correct maintenance methods, we can extend the service life of stainless steel and keep it clean.

Stainless steel screen surface dust and easy to remove dirt, available soap, weak detergent or warm water washing. Stainless steel surface of the trademark, film, with warm water, weak detergent to wash, binder composition, the use of alcohol or organic solvent scrub. Wipe clean with a soft cloth, and then clean with a neutral detergent or ammonia solution or with a special detergent.

There is a dense curing film on the surface of the stainless steel screen, and the maintenance of the oxide film can ensure the effective use of the screen. There are two kinds of measures that can not be ignored in the maintenance of the maintenance film, one is the chemical method and the other is the sandblasting method.

Sand blasting (pill) method: mainly using the method of spraying micro glass beads to remove the black oxide skin on the surface of the stainless steel sieve plate.

Chemical method: the use of a pickling passivation paste and room temperature with inorganic additives of cleaning liquid for leaching. So as to achieve the purpose of whitening treatment of stainless steel.

For the surface of the stainless steel sieve plate after the oxide film treatment, the surface is a layer of no luster effect, although seemingly no luster good-looking, but more practical. And in the process of sieve plate processing, it is necessary to carry out more protection and guarantee for curling and welding.

Related Posts

Development trend of geothermal well casing

With the increasing energy consumption and environmental problems, the development of new renewable energy is becoming more and more important. Geothermal energy as a clean, renewable energy, its application prospects.

How to install and maintain geothermal well casing correctly?

Geothermal well casing is an important part of geothermal power generation system. It is a channel connecting geothermal water wells and geothermal power generation systems, providing important support for hot water transportation.