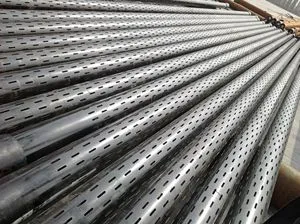

What are the defects of slotted laser processing of oil slotted screen pipe?

Stainless steel screen surface with bleach and a variety of acid adhesion, immediately rinse with water, and then ammonia solution or neutral carbonated soda solution immersion, washing with neutral detergent or warm water.

Jan 16,2023

The key to laser processing of petroleum slotted screen is to select process parameters reasonably. If the selected process parameters are unreasonable, various processing quality defects will occur, and in severe cases, the whole screen may even be scrapped.

Blast hole. The process parameter setting of perforation during single slit cutting is not suitable for perforation defects during whole tube cutting. The reason is that the laser output power is too high, the pulse frequency is too fast or the wall thickness of the sieve tube is uneven. The solution is enough to adjust the laser output power and pulse frequency.

Hook head. This defect occurs in the wide seam (seam width is greater than 1mm) processing process, the main reason is that the cutting head at the bending speed is not adjusted or the linkage between the cutting head and the screen is not well coordinated, special attention should be paid during processing.

External slag spray. This defect is caused by the low power of the laser, the fast pulse frequency and the reverse injection of slag during drilling. The laser output power and drilling pulse frequency should be adjusted to reduce or avoid slag spraying.

Extra wide. The reason for the ultra-wide is that the laser output power is too high, the feed speed is too slow, and the auxiliary gas pressure is too low in the cut barnyard, which is caused by the ablation of the screen tube matrix. The relevant parameters should be properly selected to avoid it during processing.

Internal hanging slag. It is a technical problem that is easy to appear and difficult to solve in the process of screen tube cutting. In the production, the production of hanging slag is mainly avoided by increasing the pressure of auxiliary gas and other corresponding process measures.

There are many quality defects in laser processing of oil slotted screen pipe, such as burning and cutting, uneven indexing, tapered seam, etc. The causes of each type of defect are different. We should carefully analyze the situation and take measures to improve the processing quality of screen pipe.

PREVIOUS:

Related Posts

Development trend of geothermal well casing

With the increasing energy consumption and environmental problems, the development of new renewable energy is becoming more and more important. Geothermal energy as a clean, renewable energy, its application prospects.

How to install and maintain geothermal well casing correctly?

Geothermal well casing is an important part of geothermal power generation system. It is a channel connecting geothermal water wells and geothermal power generation systems, providing important support for hot water transportation.